75 Rubber Company Limited (Z175 Factory) – Ministry of Defense is a unit with more than 50 years of research and production of technical rubber products serving the Army and the country’s economy. Besides production, Z175 Factory has always actively participated in the research of state-level research projects and projects and has achieved many achievements. In 2018, the Research Center for Polymer Materials of Hanoi University of Science and Technology was allowed by the Office of State Key Programs (Ministry of Science and Technology) to coordinate with Z175 Factory (Ministry of Defense) to implement science and technology project “Research and manufacture of high-quality heat-resistant rubber materials and conveyor belts, reinforcement and polyester screen reinforcement for industrial applications”, Code KC.02.10/16-20. In May 2020, Z175 Factory cooperated with the Research Center of Polymer Materials of Hanoi University of Science and Technology to implement the research project.

The objective of the research is to systematically study to improve the quality of 02 types of heat-resistant rubber conveyor belts, polyester mesh along with manufacturing and testing 2000 m long conveyor belts of all kinds to meet the new needs of the market.

(Following the implementation of topic content) Figure: Huu Tuyen

With the experience of basic research and application orientation of the scientific employees, on the basis of the Z175 Factory’s achieved results so far, the topic systematically researched the influence of factors on materials as well as technology to improve the mechanical properties, adhesion and heat resistance of conveyor belts.

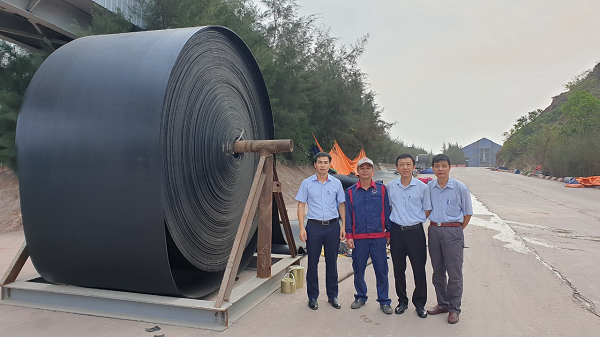

(Officers and workers of Z175 Factory participated in the project) Figure: Huu Tuyen

The obtained research results show the influence of the proportion of rubber components in the blend, the processing oil content, the content of promoters, the anti-aging agent, the co-vulcanizing agent and the vulcanizing system on the properties of product. Although the nano/submicro-sized additives such as nano-silica, nano clay, fly ash, etc., do not significantly affect to the mechanical properties or adhesion to the core before aging, they change the thermal conductivity and improve the heat resistance of the product. The optimization of the components in the single mix has not only increased the mechanical properties, adhesion and resistance to thermal aging but also allowed to shorten the conveyor processing time, thereby making it possible to energy cost savings during actual production.

The physical and mechanical strength of the fabricated rubber blends is more than 24.5 Mpa for tensile strength, elongation is more than 500%, adhesion to reinforcement is greater than 15d ± 15 and greater than 7.2 kgf./cm with polyester screen, together with aging coefficient reached in the range of 0.7 – 0.92 after aging 168 hours at 1500C.

|

|

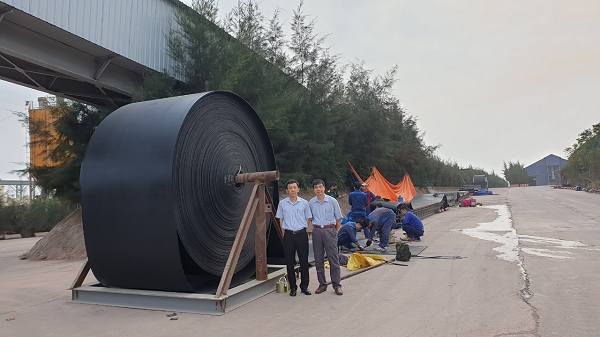

(Deploying the topic at project) Figure: Huu Tuyen

However, the product of project is not only improving the existing quality of the conveyor belt but also most importantly, obtaining a data system that allows the company’s technical staff to adjust quickly and flexibly mechanical and thermal properties of the conveyor belt depending on customer requirements.

In the coming time, the research results will be widely applied in practice, meeting the needs of the market, increasing competitiveness with major brands in the world. Key application in the production of building materials (cement, iron and steel, bricks, etc.)

Tiếng Việt

Tiếng Việt